Recent geo-political events have shaken the bedrock of the most well-established supply chains and has placed extreme focus on controlling costs. Change is always difficult but there are ways to make re-sourcing less painful.

How do you pick up one supply chain, move it a continent or two, drop it back down and expect to replicate the same exact product?

Success depends on being prepared with data and being able to clearly define the specific properties of each material component, their individual requirements and the expected physical properties and performance of each fabric, trim and finished product.

Knowing the fiber content, weight, construction and cost of a fabric isn’t nearly enough when you need to instantly find another source. Having greater detail regarding yarn sizes, density, dye type, dye method, mechanical and chemical finishes, along with a detailed listing of physical properties and a history of physical testing to back it all up will make re-sourcing much faster than starting from scratch. This information is readily available and should be captured through standard business processes that are focused on quality and compliance. Doing so as your Standard Operating Procedure makes it easier to re-source.

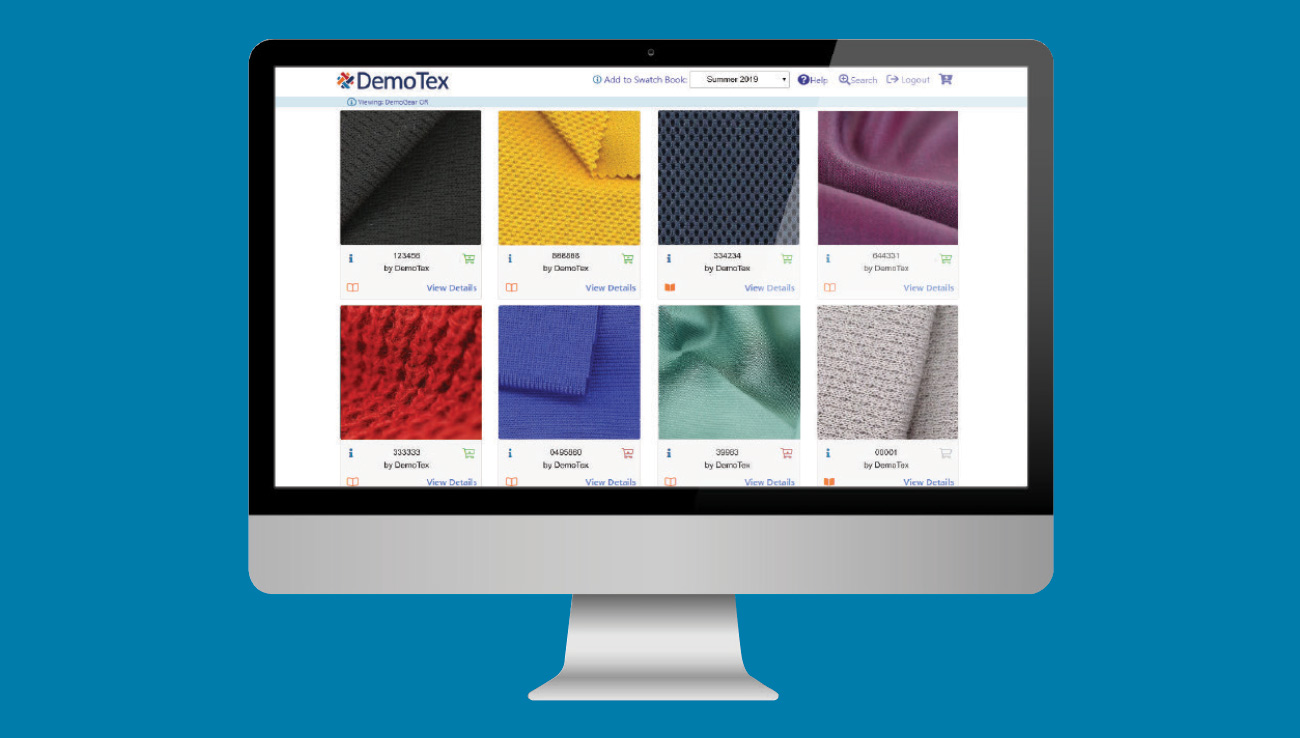

Texbase can help. Our customers have seen how our collaborative software solution not only increases the speed with which new products are developed but also drastically simplifies the process of re-sourcing.

One example is Texbase Material Connect which allows brands to define the data necessary to evaluate a new fabric or component and have their suppliers enter and update that data in real time. This eliminates sending templates by email, thereby capturing the data you need to make re-sourcing much easier.

Please email us at MoreInfo@Texbase.com or visit www.Texbase.com for downloads and demo videos.